See Details Below

Small Improvement Projects Playbook- A Field Guide to SIP

Small Improvement Projects (SIPs) are short-term, action-oriented projects designed to enhance reliability, efficiency, and workplace conditions. The primary goal of SIPs is to eliminate defects, reduce maintenance requirements, and increase asset performance. These projects focus on quick, impactful improvements that can be completed within a three-month timeframe.

Unlike other books in the series, Small Improvement Projects Playbook is not a comic. It is an informal workbook designed for anyone who wants to organize, eliminate defects, and improve maintenance.

Key Characteristics of SIPs

- Focused on action rather than lengthy analysis.

- Address defects, damage, and waste in processes or equipment.

- Require minimal investment and resources.

- Aim to engage stakeholders and foster a culture of reliability.

- Provide measurable improvements in cost, efficiency, and safety.

Finding and Choosing a SIP

- Start with “Defects in Your Face” (DIFY): These are visible defects that disrupt workflow, such as leaks, loose bolts, or safety hazards

- Use brainstorming sessions to generate ideas.

- Prioritize small, high-impact projects that can be completed quickly and require minimal approvals.

- Avoid projects that are too large, complex, or speculative.

Planning and Execution

- Define the goal, expected outcome, and method of measurement.

- Develop an SIP plan that outlines specific actions, responsibilities, associated costs, and clear timelines.

- Utilize scorecards to track progress and maintain visibility.

- Leverage existing resources and team collaboration for successful execution.

Metrics and Measurement

- Lagging indicators : These measure past performance, such as downtime or maintenance costs.

- Leading indicators : Predict future success, such as defect elimination rates or process efficiency.

- Effective SIPs focus on actions that influence leading indicators to drive long-term improvements.

Team Collaboration and Meetings

- Teams should meet regularly to review progress, discuss challenges, and refine strategies.

- Assign clear roles and responsibilities to ensure accountability.

- Use structured agendas and meeting minutes to keep SIPs on track.

Small Improvement Projects Playbook- A Field Guide to SIP

Final Thoughts

SIPs are a powerful tool for continuous improvement, enabling organizations to reduce maintenance workloads, improve reliability, and foster a proactive culture. By starting small and focusing on defect elimination, companies can achieve significant long-term benefits with minimal disruption.

You have just enjoyed an excerpt from:

Small Improvement Projects Playbook- A Field Guide to SIP

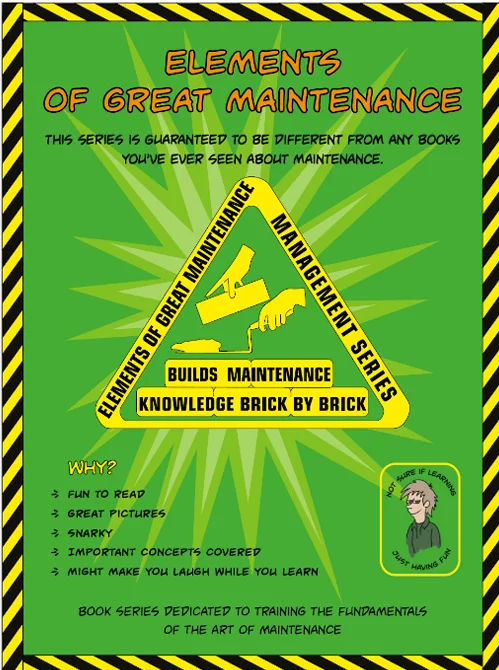

is part of a series of books called Elements of Great Maintenance Management

Elements of Great Maintenance Management book series of full-color, fun, humorous graphic novels that demonstrate the basics of Maintenance.

There are 8 in the series so far. And by the way, we are writing new ones all the time. Contact me, Joel by email JDL@Maintrainer.com for any questions